VMC Feeler VMP 40A

- Travel Capacity: X-axis: 1,000–1,020 mm | Y-axis: 520 mm | Z-axis: 500–505 mm

- Spindle Performance: Speed: Standard 10,000 RPM (Belt-driven) | Power: Approximately 11–18.5 kW | Taper: BT40 or CAT40

- Control Systems: Commonly equipped with FANUC (e.g., Series 0i-MF), but also available with Siemens or Mitsubishi units.

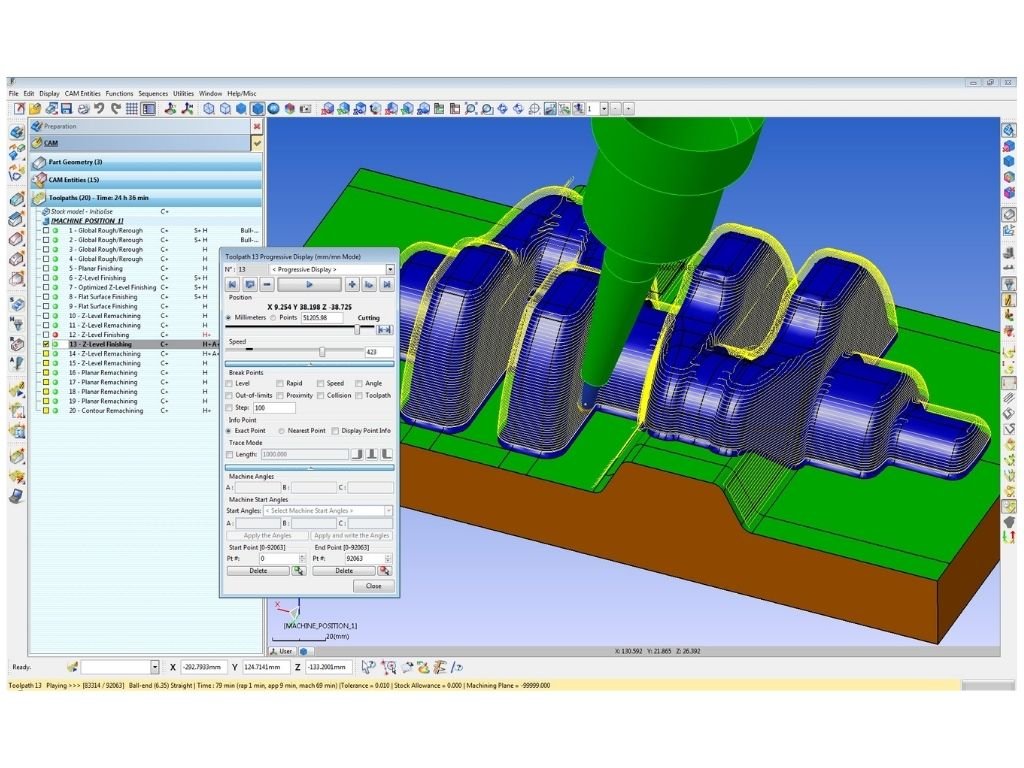

The FEELER VMP-40A is a high-precision Vertical Machining Center (VMC) manufactured by Fair Friend Group (FFG). It is designed for heavy-duty cutting and long-term accuracy in industries such as automotive, aerospace, and mold making.

Structural Rigidity: Built with high-quality Meehanite cast iron for superior damping and thermal stability.

Guideway Design: Typically uses linear guideways on the X and Y axes for high-speed traverse (up to 40 m/min) and boxways on the Z-axis for increased cutting stability.

Precision Technology: The machine's design is validated through Finite Element Analysis (FEA) to ensure accuracy under heavy loads.

Optional Equipment: Can be configured with a 4th-axis rotary table, through-spindle coolant (CTS), and chip conveyors.